Understanding and managing the temperature during fermentation is critical for producing the best possible flavors in your homebrewed beer, wine, or any other fermented product. Fermentation is a biological process driven by yeast or bacteria, converting sugars into alcohol and other compounds, and the temperature at which this process occurs has a profound impact on the final taste and quality of your product.

Ensuring that your fermentation is taking place within the optimal temperature range is essential for yeast health and activity, which in turn influences the entire flavor profile and stability of your beverage.

Temperature-controlled fermentation allows brewers and vintners to create a consistent and controlled environment, preventing the development of off-flavors and undesirable characteristics in their brews. Various methods are available, ranging from simple DIY solutions to advanced temperature control systems.

These methods promote consistency and can help prevent common fermentation problems that can arise from temperature fluctuations. By paying close attention to fermentation temperatures, you’re also protecting your brew from harmful microorganisms that thrive outside the ideal temperature range, ensuring a successful and clean fermentation process.

Key Takeaways

- Controlling fermentation temperature is vital for optimal yeast performance and flavor development.

- A range of technologies and methods can be used to maintain desired fermentation temperatures.

- Effective temperature control also safeguards against spoilage and off-flavors.

Fundamentals of Fermentation

Fermentation is a critical process involving yeast, temperature, and various stages to produce alcohol and CO2 from glucose.

The Role of Temperature in Fermentation

Temperature plays a pivotal role in your fermentation process. Specific temperature ranges are essential for the survival and activity of yeast. Ales are typically fermented at warmer temperatures (15-24°C), which promotes rapid yeast activity and faster fermentation. Lagers, on the other hand, require cooler temperatures (7-13°C) to ferment properly.

Yeast Strains and Temperature Variability

Your choice of yeast strain can tolerate different temperature ranges which affect the flavor and quality of beer. Some strains are more versatile and can produce desirable flavors across a broader range of temperatures, whereas others might produce off-flavors if the temperature deviates from the ideal range.

Chemistry of Fermentation

In the fermentation process, yeast converts glucose into alcohol and CO2, creating the desired flavor profile and carbonation in beverages. The efficiency and outcome of these chemical reactions are significantly influenced by pH levels and fermentation temperature.

Fermentation Types

- Spontaneous Fermentation: Relies on naturally occurring yeasts and bacteria.

- Lactic Acid Fermentation: Primarily carried out by lactic acid bacteria, transforming sugars into lactic acid.

Mesophiles, such as lactic acid bacteria, perform optimally at moderate temperatures and are utilized in various forms of fermentation.

Fermentation Stages

The fermentation process is commonly divided into primary and secondary stages. During the primary stage, the majority of the alcohol and CO2 is produced as yeast ferments the available glucose. In the secondary stage, the activity of yeast decreases, and the beverage matures, developing a refined taste.

Temperature control is key during these stages to ensure yeast remains active and produces the desired end products.

Temperature Control Methods

Proper temperature control is critical for optimizing the fermentation process. The ability to maintain specific temperature ranges can significantly affect the flavor and stability of the final product. Here, you’ll learn about various methods ranging from active systems to evolving technologies that can help you regulate fermentation temperatures with precision.

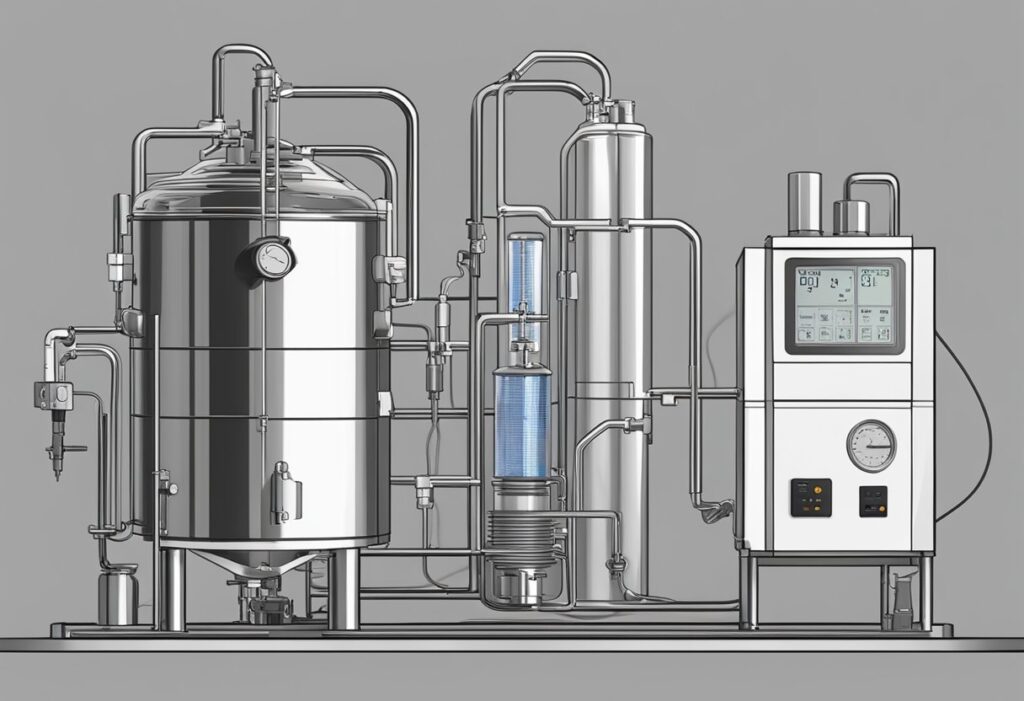

Active Cooling and Heating Systems

Active cooling and heating systems are essential for maintaining specific temperatures during fermentation. With a fermentation chamber, you can integrate a temperature controller and sensors to actively regulate the environment.

A refrigerator or freezer can be converted with a thermostat to function as a reliable fermentation chamber. These systems often use heating pads, wraps, or dedicated equipment to stabilize temperature, which you can adjust according to the yeast’s needs for optimal fermentation.

Insulation Techniques

Insulation is a passive yet effective approach to maintain a consistent temperature. You can line your fermentation chamber with insulating material like polystyrene or reflective foil, which helps mitigate temperature fluctuations. This approach is particularly useful when external temperature conditions are variable, but you need to ensure that your fermenting product remains stable.

Water Baths and Ice Baths

A water bath or ice bath provides a simple method for temperature regulation. By submerging fermentation vessels in water, and adding or removing ice as necessary, you can create a thermal buffer that slows temperature changes. It’s a lower-tech solution, but with careful monitoring, you can maintain a fairly consistent range suitable for many fermentation projects.

Evolving Technologies in Temperature Regulation

Recent advancements in fermentation technology have introduced more sophisticated methods for temperature control. These include glycol-jacketed conical fermenters with integrated cooling and heating systems that allow you to precisely control temperature through a digital interface. As these technologies become more accessible, they offer an enhanced level of control for the serious home brewer or professional.

Specific Fermentation Practices

In temperature-controlled fermentation, specific practices are necessary to produce different beer styles with distinct flavors. Understanding and applying the correct temperature range for each fermentation type is crucial to brewing quality beer.

Ale Fermentation

Ales are one of the two major categories of beer, characterized by their top-fermenting yeast. Your ale fermentation should occur at warmer temperatures, typically between 60°F and 75°F (15°C to 24°C). Fermenting ales at this range encourages the yeast to produce desirable fruity and floral esters, adding complexity to your beer. However, too high a temperature can yield unwanted off-flavors, so precise fermentation temperature control is necessary.

Lager Fermentation

In contrast, lager fermentation involves bottom-fermenting yeast and requires cooler temperatures, usually between 45°F and 55°F (7°C to 13°C). By keeping your lagers at these temperatures, the beer will have a cleaner, crisper flavor profile which is typical for this style. It’s essential to maintain this lower temperature range consistently to avoid the production of off-flavors that can occur with temperature fluctuations.

High-Gravity Brewing

For high-gravity brewing, control over the fermentation temperature becomes even more critical. High-gravity beers contain more sugars from the malt, leading to a higher alcohol content when the yeast ferments these sugars.

This process generates significant heat, which can hinder yeast performance and promote the formation of fusel alcohols that negatively affect flavor. Managing fermentation temperatures carefully ensures that you preserve the desired IBU and HA levels, and develop the characteristic taste profiles of strong beers without compromising quality.

Troubleshooting Fermentation Issues

In fermentation, temperature is a critical factor, affecting yeast activity, flavors, and the risk of contamination. Effective management strategies are vital for a successful fermentation process.

Managing Off-Flavors and Contamination

Cold temperatures can slow down yeast activity, leading to incomplete fermentation. This can result in off-flavors or higher chances of contamination. Ensure sanitation protocols are strictly followed to minimize the risk of spoiling your batch. If you detect off-flavors or signs of contamination, assess your process for potential sanitation lapses.

Addressing Temperature Fluctuations

Temperature stability is key to consistent fermentation. If the fermentation temperature is too cold, consider using evaporative cooling to gently warm the environment. Conversely, if ambient conditions are too warm, you can employ methods like ice baths. Using a temperature probe can help you monitor the conditions more accurately. Always keep your fermentation away from areas with significant temperature changes.

Dealing with Incomplete Fermentation

If you suspect incomplete fermentation, first check the fermentation temperature. It should be within the optimal range for the type of yeasts used. If it’s too cold, moving your ferment to a warmer spot or using a fermentation heater can help. Moreover, ensure that you’re pitching enough viable yeast. Room temperature can play a part too; it should be consistent and appropriate for the yeast’s needs to avoid incomplete fermentation.

Homebrewing Applications

Temperature control is a pivotal aspect of homebrewing that can determine the quality and flavor profile of your beer. Precision in this area allows you to replicate styles accurately and improve your brewing results significantly.

Building a DIY Fermentation Chamber

To create a DIY fermentation chamber, start by insulating a space that fits within your budget and spatial constraints. You could convert an existing piece of furniture like a cabinet, or build something from scratch using insulation panels.

Next, integrate a temperature controller with a refrigerator or freezer to regulate the internal temperature. This setup can be as simple as connecting both devices or more sophisticated with additional features like heating elements for cooler months.

Selecting Equipment for Homebrewers

When choosing equipment, prioritize durability and accuracy. A reliable temperature controller is essential for maintaining consistent brewing conditions. Homebrewers often opt for dual-stage controllers that can both cool and heat. In terms of cooling, a refrigerator or freezer that is large enough to hold your fermenter is crucial. Look for energy-efficient models to keep operational costs down, especially if you’re brewing throughout the year.

Utilizing Seasonal Temperatures

Leverage the winter months to brew lagers or other styles that require cooler fermentation temperatures, as this can often be achieved with minimal equipment. During warmer seasons, focus on ales or use evaporation cooling techniques. Remember that room temperatures can fluctuate, so even if it’s cool outside, you may need to monitor and adjust the fermentation temperature to maintain optimal brewing conditions.

Advanced Topics in Temperature Control

Understanding the intricacies of temperature control in fermentative processes enhances your ability to produce superior products. Whether you are crafting beer or fine-tuning the fermentation of other products, the marriage of engineering and biochemistry is critical. Here, delve into sophisticated systems, the biochemical impacts of temperature, and the resulting sensory nuances.

Engineering Better Temperature Control Systems

For optimal controlled fermentation, you need precise engineering solutions. Temperature controllers and thermowells are vital in maintaining the desired parameters during fermentation.

Incorporating advanced experimental design methods, you can develop a controller that not only stabilizes the temperature but also adapts to the varying needs of different beer styles or other fermented products. These engineering feats ensure that fermentation occurs under ideal conditions, conducive to both efficiency and quality.

The Science of Esters and Fusel Alcohols

Your understanding of the fermentation process is incomplete without a grasp of the biochemical outcomes influenced by temperature. The formation of esters and fusel alcohols — flavor compounds critical to the character of fermented beverages — is highly sensitive to temperature changes. By controlling the fermentation temperature, you can manipulate these compounds to enhance desirable flavors and minimize off-flavors, giving you a strategic advantage in flavor profiling.

Exploring the Impact of Temperature on Sensory Profile

Temperature exerts a significant influence on the sensory profile of your fermented products. The complex interplay of yeasts and fermentation conditions dictates the aroma, taste, and mouthfeel of the final product.

By employing a controlled fermentation approach, you leverage temperature as a tool to fine-tune these sensory components. Through methodical experimental design, discern the precise temperature effects on your product’s appeal and quality, ensuring each batch meets your exacting standards.

Conclusion

Temperature-controlled fermentation is a paramount step in ensuring the quality and consistency of fermented products. Your approach to managing temperatures during fermentation can influence flavor profiles, fermentation speed, and final product safety. Precise temperature control throughout fermentation processes brings forth a balance of microbial activity, optimal product yield, and desired organoleptic properties.

- High temperatures can lead to rapid fermentation but may risk product spoilage and off-flavors.

- Lower temperatures generally extend fermentation duration but can enhance flavors and stability.

Employing fermentation temperature control systems, you warrant that your fermentative goods reach their highest potential with regard to texture, taste, and aroma. Choose the right temperature regime for your fermentation needs, be it in baking, brewing, dairy, or other fermentation-based industries.

- Consistency: You achieve batch-to-batch consistency.

- Quality: You safeguard the quality of your fermentative products.

- Efficiency: You optimize the fermentation times and energy use.

By controlling fermentation temperatures, you also contribute to the safety profile of your products by inhibiting the growth of undesirable microorganisms. This vigilance ensures you comply with food safety regulations and exceed consumer expectations.

Remember, precision in temperature control translates to excellence in your fermentation endeavors. Embrace advanced technologies and methodologies to maintain this precision and witness your products thrive in both quality and popularity.